Ripple Strip Fire Protector

RIPPLE STRIP FIRE PROTECTION - FOR SEALING CORRUGATED ROOFS AGAINST EMBER ATTACK

We now manufacture and supply RIPPLE STRIP PACKS for sealing Corrugated Roofing Perimeters against hot burning embers, insects / vermin & wind or rain.

Good for sealing roof entry points against attack from fire!

Good for reducing outside noise.

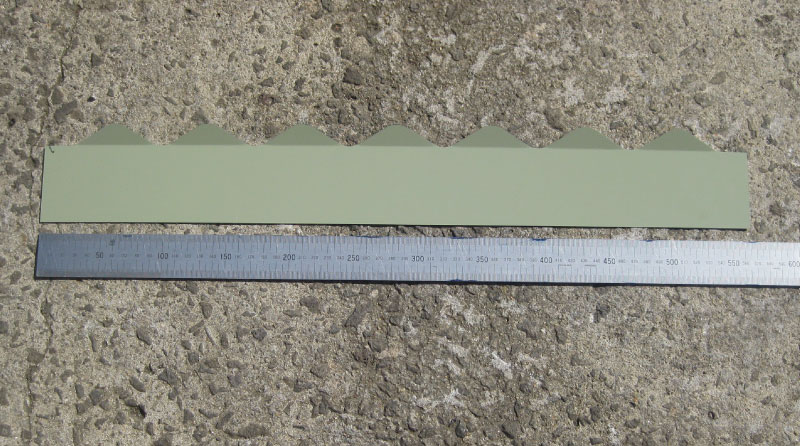

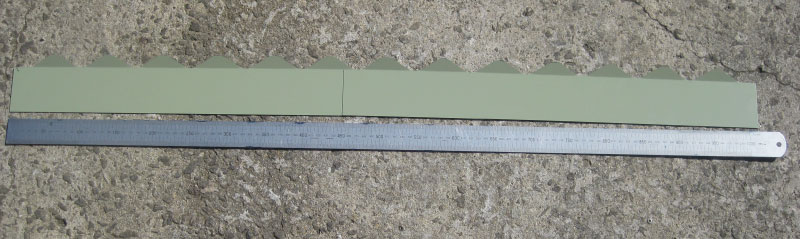

Standard Length = 565mm long pieces. Please see picture above.

Overall Height = 80mm. - 60-62mm of flat area.

Overlap distance on either side = 20mm extra either side for mounting screws to screw both overlapping pieces together.

RIPPLE STRIP MADE TO ORDER

Ripple Strip should be made to order as customers will have different requirements, so please write to us or let us know what you require.

Ripple strip can be used under or ontop of a corrugated roof and also along the top of the roof ridge.

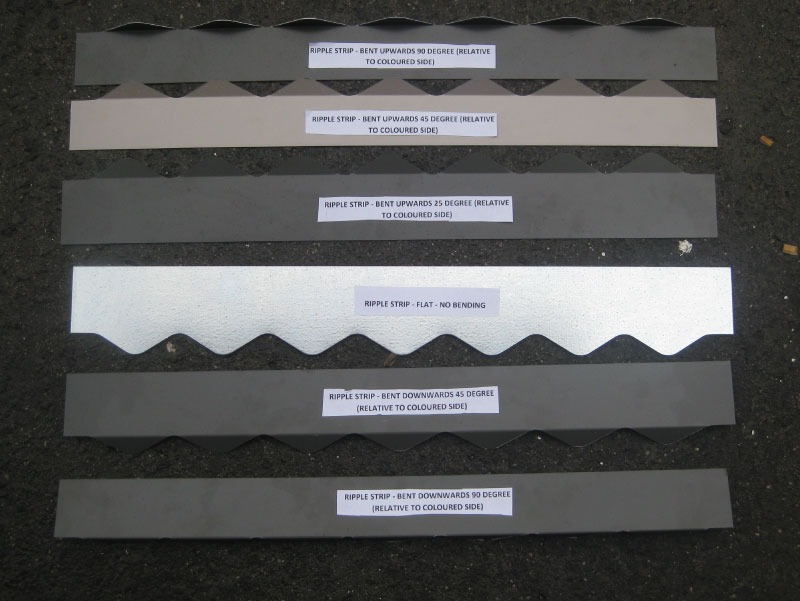

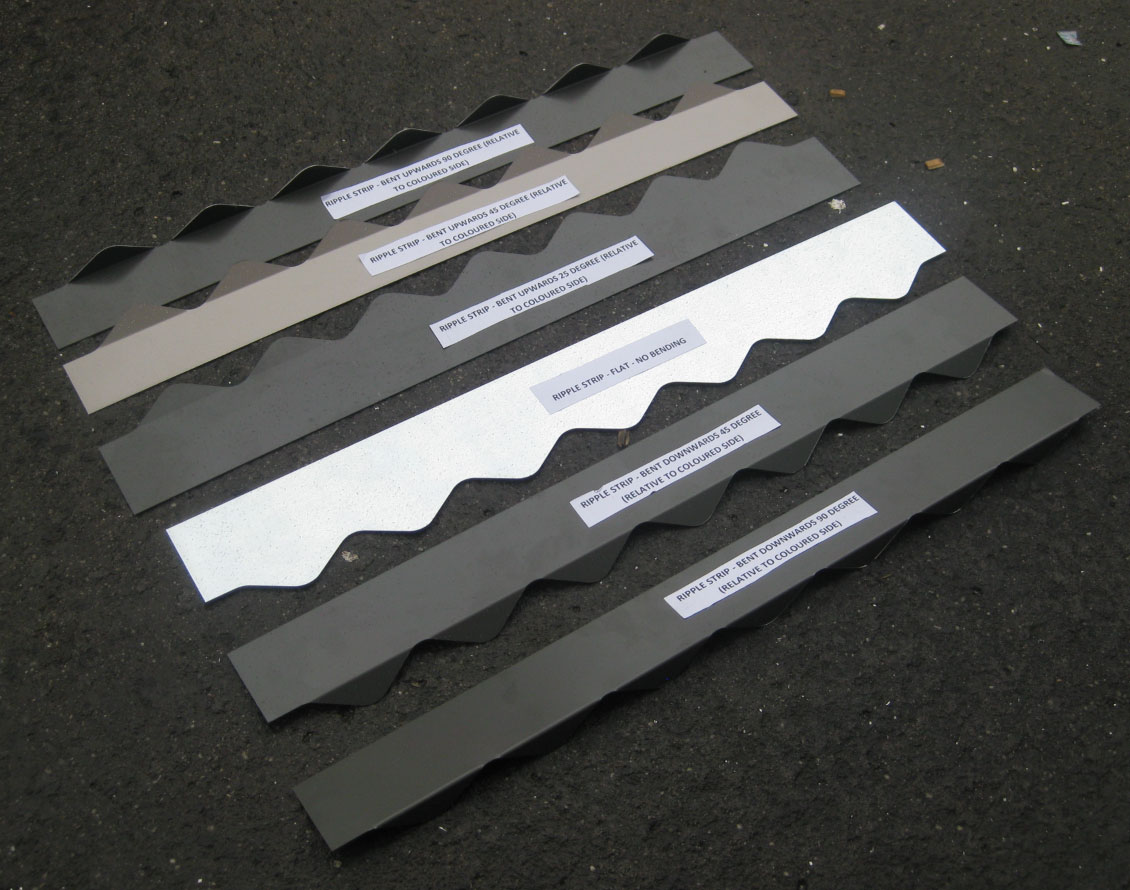

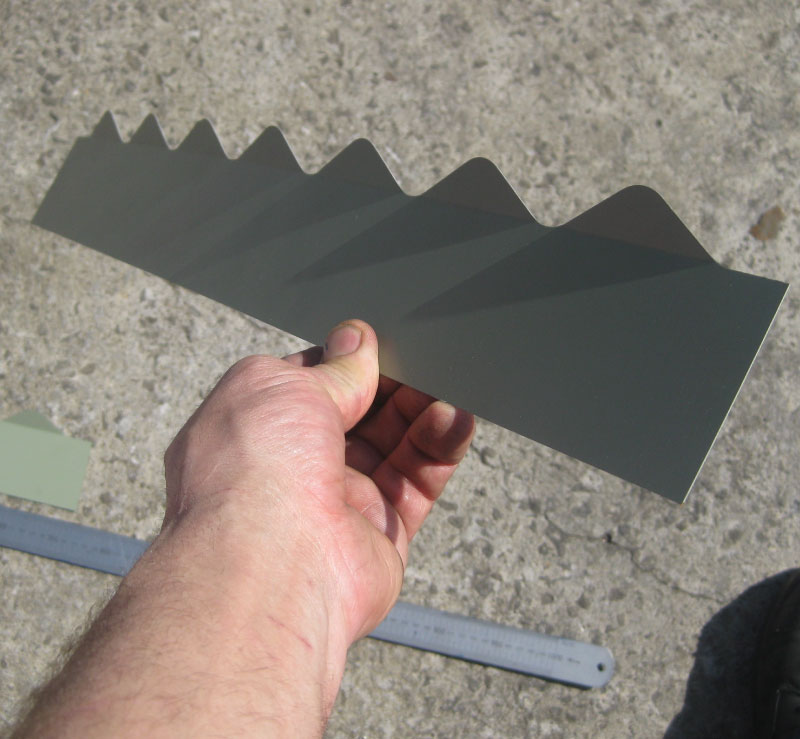

DIRECTION OF BEND

The direction of bend will be different depending on how you intend to use it and also angle of roof may be different.

MOUNTING UNDERNEATH A CORRUGATED ROOF

For mounting Ripple Strip underneath a roof the corrugations are bent upwards relative to the coloured side. Please refer to picture below.

For Ripple Strip mounted underneath a roof we usually pre-bend to fit standard Australian roof pitch angle of 25 degrees.

So the corrugated part is bent 25 degrees upwards relative to the coloured side as shown in picture below.

(Standard angle can be altered if requested by customer).

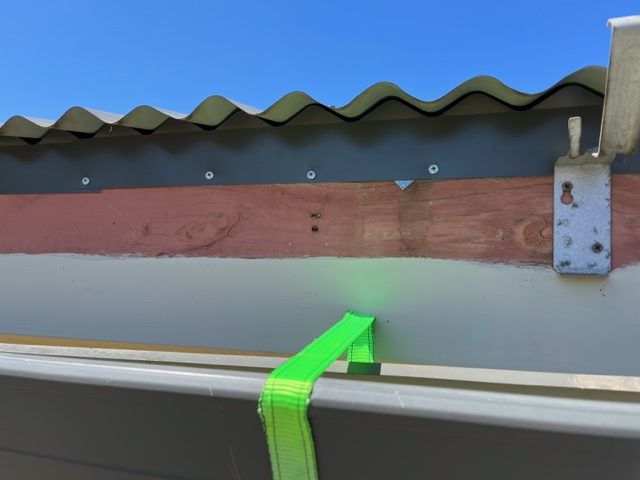

The photo above shows an example of Ripple Strip being used to seal underneath the corrugated roof.

The ripple strip should be positioned right against the corrugations but the fascia board was shorter than normal below example.

We can make ripple strip different widths aswell which would have solved the below issue.

MOUNTING ONTOP OF A CORRUGATED ROOF

For mounting Ripple Strip ontop of the roof the corrugations are bent downwards relative to the coloured side.

So the corrugated part is bent 25 degrees downwards relative to the coloured side. Picture coming soon.

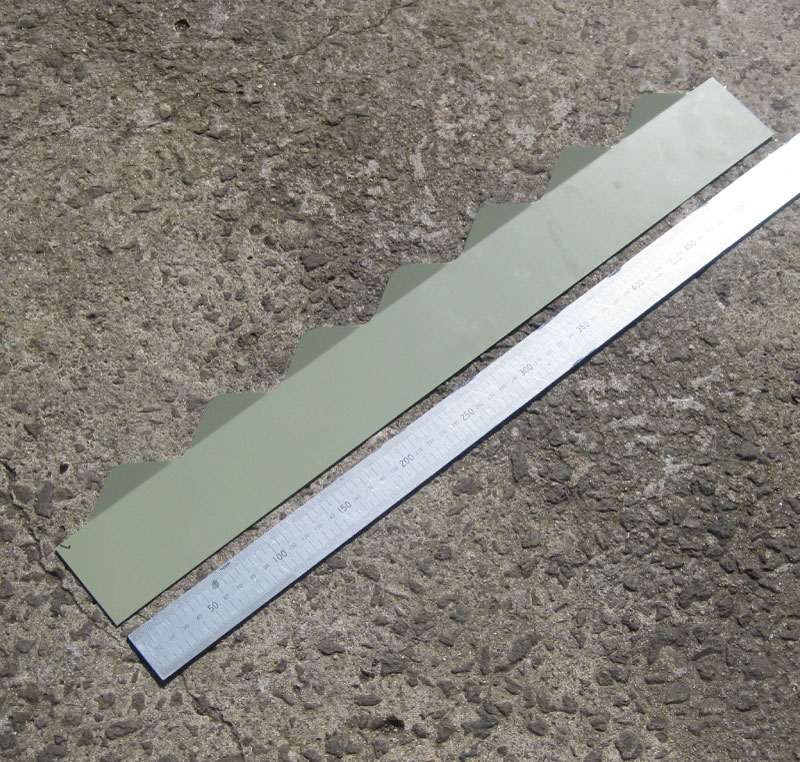

MOUNTING ON ROOF RIDGE

And for mounting on either side of a roof ridge line or roof capping, the corrugations are to be bent downwards at 90 degrees relative to the coloured side of the colorbond.

The photo below shows an example of how the ripple strip can seal a top roof ridge.

Please note the ripple strip will obviously be mounted further up the roof to seal the roof ridge top capping.

For Ripple Strip pre-bent to fit standard Australian roof pitch angles of 25 degrees. (Standard angle can be altered if requested by customer).

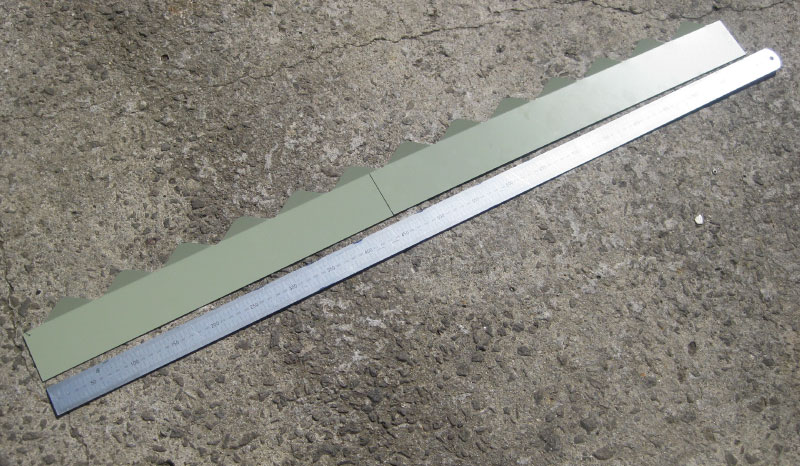

RIPPLE STRIP now comes in standard PACKS - with QTY = 40 pieces of 565mm long

Each RIPPPLE STRIP Pack = 20 Linear metres of roof area - including overlapping.

Two individual pieces of 565mm lengths overlapped together = 1 meter approximately. Please refer to picture below:

Ripple Strip is cut with corrugated pattern to fit neatly to the underneath or sides of standard colourbond corrugated roof sheets.

Ripple strip can be overlapped to seal properly.

Can be trimmed onsite with tin snips to suit exact roof length.

Ripple Strip is to be fixed to sides of walls or fascia boards with self tappers.

You can then apply silicone sealants to seal around corrugated profle between ripple strip and roofing sheets.

Ripple Strip comes in any commonly available Colorbond colour.

When ordering please tell us what Colorbond colour you require.

You can now order Ripple Strip Packs online below

If interested please write to us at speedex@speedex.com.au

**Please tell us in notes what Colorbond colour you require!!

And also what angle bend and direction of bend.

We also supply as flat pieces with no bends

Or Email us: speedex@speedex.com.au

There are no products to list in this category.